Understanding the Role of Vacuum Valves in Industrial Systems

Vacuum valves play a pivotal role in ensuring the efficiency, reliability, and safety of vacuum systems across various industrial sectors. These components regulate the flow of gases and maintain the desired vacuum level in a controlled environment. With different types of valves used for specific applications, choosing the right design can significantly impact the system's performance and longevity.

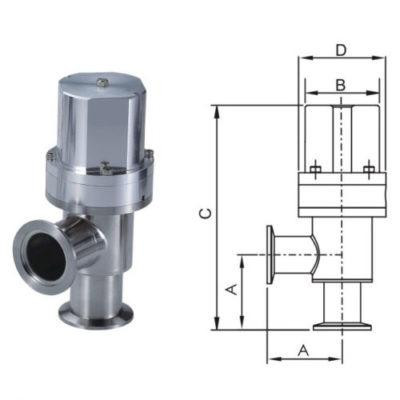

Key Features and Applications of a Vacuum Angle Valve

A Vacuum Angle Valve is commonly utilized in systems where a change in flow direction is necessary, often at a 90-degree angle. This type of valve is known for its compact structure and easy integration into pipeline layouts. It supports both high and low vacuum environments, making it versatile for semiconductor manufacturing, vacuum furnaces, and scientific research equipment. Its design minimizes dead space, reducing contamination risks and improving system hygiene. The sealing mechanisms in these valves are designed to ensure leak-tight performance, even in demanding applications involving corrosive or high-temperature gases.

Innovation Behind Vacuum Gate Valve Design

When considering large-scale vacuum systems or those that require a straight-through flow path with minimal flow resistance, Vacuum Gate Valve Design becomes crucial. This type of valve operates by moving a gate or blade in and out of the path of the gas flow. The design is engineered for ultra-high vacuum applications where minimal particulate generation and zero leakage are critical. Modern advancements in this design focus on low-profile bodies, optimized sealing technologies, and durable materials to extend service life under continuous operation. Gate valves are often favored in particle accelerators, coating systems, and cleanroom environments due to their robust sealing and smooth operation.

Choosing the Right Valve for Optimal System Performance

Each vacuum system has unique requirements based on factors like operating pressure, flow rate, temperature, and system configuration. While angle valves provide simplicity and compactness, gate valves offer full bore openings and better flow characteristics for certain applications. Engineers must carefully assess system needs, including maintenance accessibility and cycle life, to choose between valve types. Selecting the correct valve not only improves performance but also reduces downtime and maintenance costs in the long term.

The Importance of Material and Seal Selection in Vacuum Valves

Both angle and gate valves rely heavily on the quality of materials used in construction. Stainless steel is the standard for body material due to its strength and corrosion resistance. Seals, typically made of elastomers or metal, are critical for ensuring vacuum integrity. In high-temperature or chemically reactive systems, metal seals offer better durability, while elastomer seals may be ideal for general-purpose applications. Understanding the specific environment where the valve will be used is essential for long-lasting functionality.

Enhancing System Reliability with Quality Valve Solutions

High-performance vacuum valves contribute to overall system stability. Whether it’s achieving consistent pressure levels, preventing backflow, or minimizing contamination risks, the right valve enhances productivity and quality. Many industries today prioritize modular valve designs that offer ease of maintenance and replacement without significant downtime.

For reliable, high-quality vacuum components including advanced angle and gate valves, you can visit vacuumchamber.com, where a wide selection of industrial-grade products is available to meet various engineering needs.

For info. - Linkedin

Comments on “Precision in Vacuum Systems with Advanced Valve Technology”